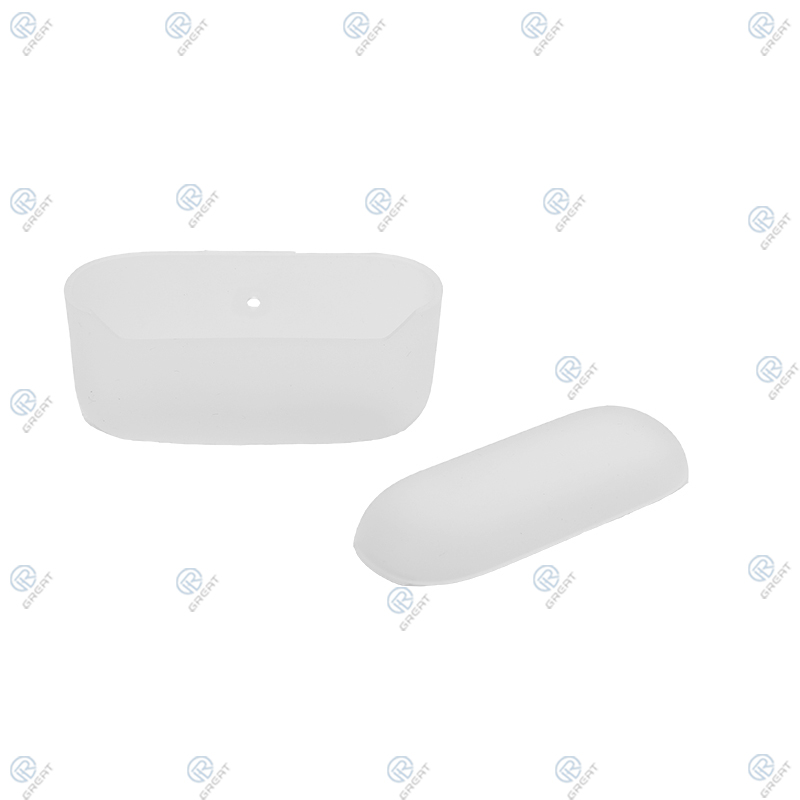

SIR+Plastic Case

Secondary moulding, package plastic products, good bonding performance is not easy to fall off.

Low temperature secondary moulding using platinum vulcanising agent, beautiful appearance, comfortable hand feeling, non-toxic and tasteless, can be directly in contact with the skin.

Wear-resistant, low-temperature resistance, waterproof, dustproof, insulation, shockproof, flame retardant.

Material need to choose can use platinum low temperature vulcanisation production of silicone, plastic need to choose.

Can withstand more than 120 degrees temperature, such as PC / nylon / PBT.

Commonly used hardness 40-60 degrees, colour size material can be customized according to customer demand.

The surface can do UV anti-static treatment and oil spraying treatment, can pass the alcohol test, eraser test and so on.

Raw edge is less than 0.1mm

Widely used in electronic products, household appliances, toys and other industries.

Get A Free Quote

ShenZhen Great Technoloy Co., Ltd. was founded in 2005, specializing in the research and development, production and sales of silicone and rubber products.

Related products

-

Walkie-talkie housing

One-stop one-piece customisation of walkie-talkie housings and internal parts

-

Earphone charging case inlay

Protective case for headphone charger, beautiful appearance, comfortable hand feeling

-

Earphone Charging Case

Protective case for headphone charger, beautiful appearance, comfortable hand feeling

-

Transparent Protective Case

Can do different transparency, different size, different hardness of the protective sleeve, according to the drawing custom specifications, commonly used hardness 30-60 degrees.