LSR injection molding process

LSR injection molding process

Liquid silicone injection process is an energy-saving and environmentally friendly silicone production process, which injects liquid silicone into the mould through the feeding system, and then make the silicone products through the combined action of heat, pressure and time. Compared with the compression moulding process, its use of injection process can produce more complex silicone products. Its use of liquid silicone raw materials, low volatility, low molding temperature, more environmentally friendly and energy saving. It is widely used in the medical and food industries.

Its typical production process is:

LSR A+LSR B+colour dispersion→injection→molding →QC→after moulding process

Advantages of injection process

1, can produce silicone products with complex shapes, automated process possible.

2, better control of the material weight and position of the injection, so that the rubber distribution is more even which resulted in better dimensional accuracy.

3, during the entire molding process, LSR flow inside a closed tunnel (the barrel,feeding system and mold), so not easy to be contaminated, the production yield rate is higher, especially for the light color products.

4, the production of low-temperature molding, more energy-saving, in line with the concept of “green production”.

5, the raw material is environmentally friendly, especially suitable for medical, food and other industries.

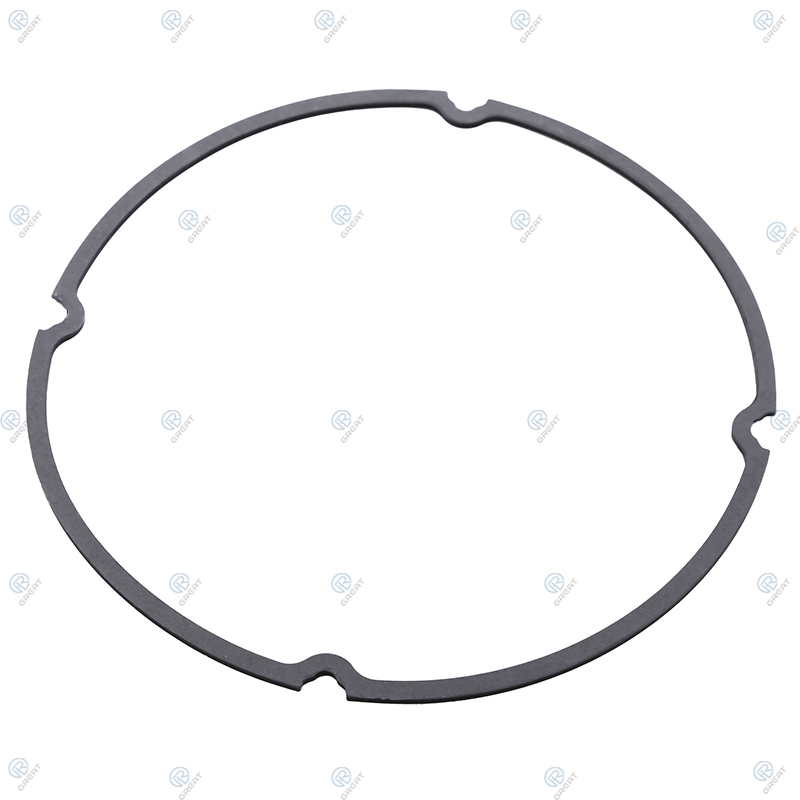

Related products

Get A Free Quote

ShenZhen Great Technoloy Co., Ltd. was founded in 2005, specializing in the research and development, production and sales of silicone and rubber products.