Post-treatment process selection

Post-treatment process selection

After the product is molded, a post-treatment process is required to remove the parting line flash of product, and Great offers a variety of post-treatment processes for option:

Die-cut – For regular shaped products

Advantages: high production efficiency, low cost; better control of the flash, can be achieved <=0.1mm.

High pressure gas tearing – for products with a hardness of 50-80 degrees, with a certain thickness and no right-angled

Advantages: high production efficiency, low cost, flash quality depend on tooling cutting edge and moulding quality.

Freezing trimming-applicable to products with hardness of 40-80 degrees, the mould cutter needs to be specially designed.

Advantages: high production efficiency, low cost; better flash control, can do <=0.05mm

Grinding process-applicable to various types of products

Advantage: through the grinding process, can achieve 0 batch edge.

Manual trimming – applicable to all types of products

Disadvantages: Higher production costs; flash quality not stable.

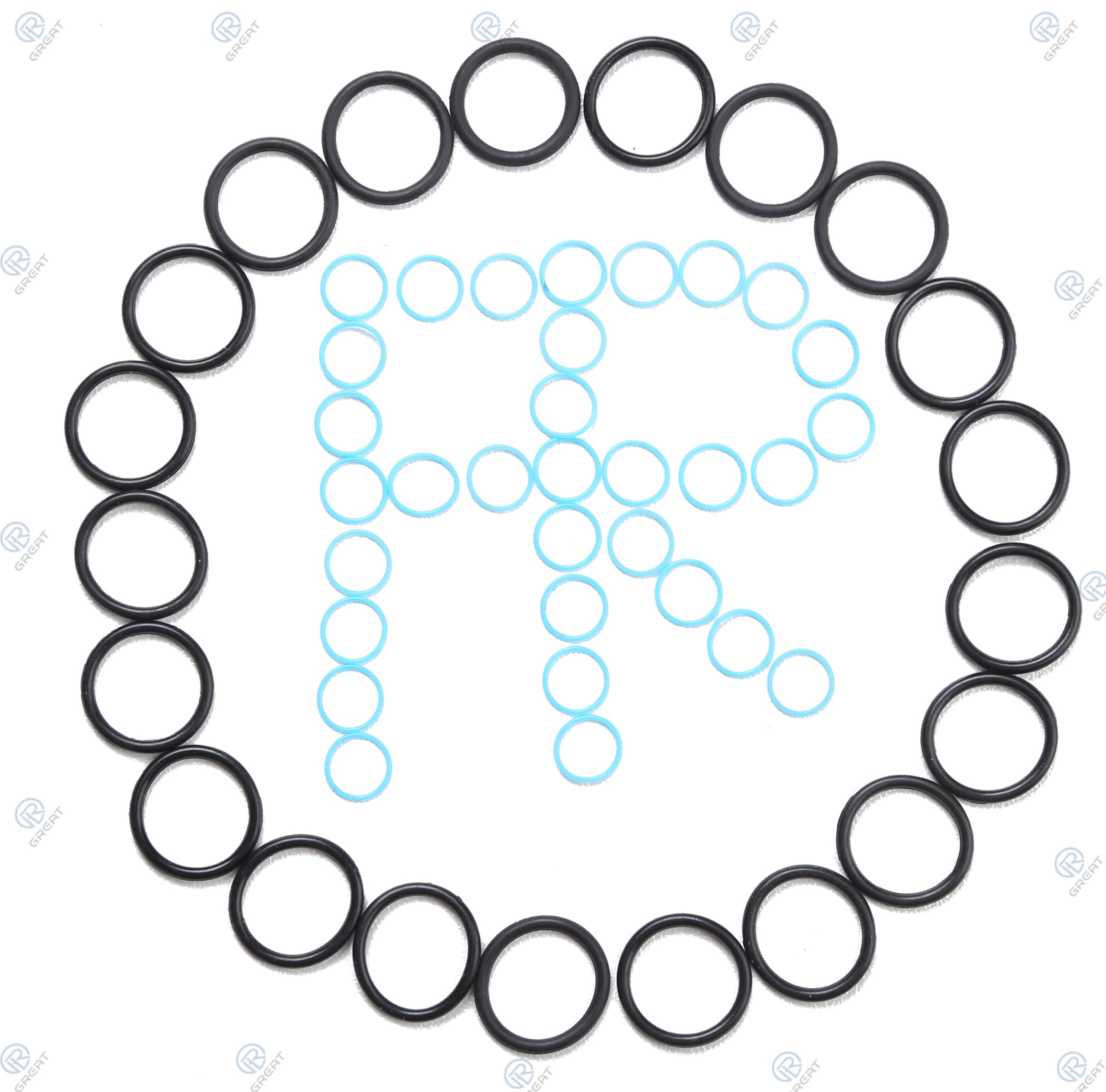

Related products

Get A Free Quote

ShenZhen Great Technoloy Co., Ltd. was founded in 2005, specializing in the research and development, production and sales of silicone and rubber products.